Kuhnke Solenoids

Browse Kuhnke Solenoids by type

-

Linear Solenoids - Open Frame

- Open frame design.

- 2mm up to 20mm stroke length.

- Push / pull or combination type with return spring.

- Flying lead connections.

-

Linear Solenoids - Compact Design

- Compact cylindrical design.

- 3mm up to 40mm stroke length.

- Push / pull or combination type with return spring.

- Nose mounting.

-

Linear Solenoids - Heavy Duty

- Powerful heavy duty square design.

- 8mm up to 20mm stroke length.

- Double output shaft - threaded / clevis.

- Surface mounting.

-

Rotary Solenoids - Heavy Duty

- Powerful heavy duty square design.

- 25°, 35°, 45°, 65° and 95° rotary movement.

- Clockwise or anti-clockwise rotation.

- Optional return spring.

-

Rotary Solenoids - Compact Design

- Compact cylindrical design.

- 25°, 35°, 45°, 65° and 95° rotary movement.

- Clockwise or anti-clockwise rotation.

- Optional return spring.

-

Bi-stable Linear Solenoids - Open Frame

- Open frame design.

- 2.5mm up to 8mm stroke length.

- Two-directional operation.

- Flying lead connections.

-

Holding Solenoids - Compact Design

- Compact cylindrical design.

- 20mm up to 70mm diameter.

- 40N up to 1,400N holding force.

- Voltage 24V DC, others on request.

-

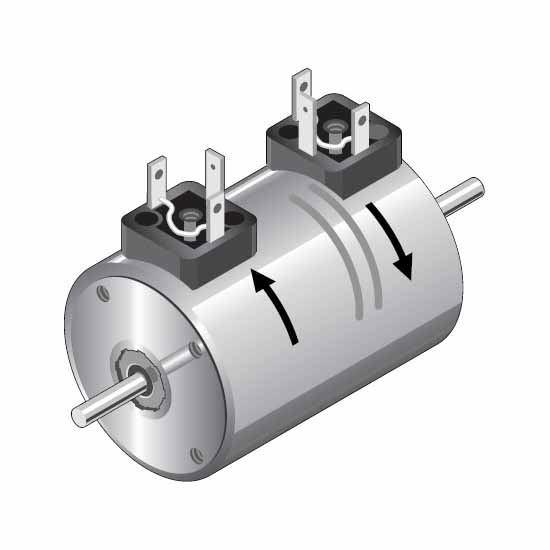

Bi-directional Rotary Solenoids

- Compact cylindrical design.

- 25°, 35°, 45°, 65° and 95° rotary movement.

- Bi-directional rotation.

- Double output shaft.

-

Bi-directional Linear Solenoids

- Open frame, square or cylindrical design.

- 3mm up to 8mm stroke length.

- Bi-directional stroke.

- Double output shaft.

In its simplest terms, a solenoid is a device that converts electrical energy into mechanical movement.

A solenoid, constructed from copper wire uniformly wound onto a spool to create an electrical coil, generates a controlled magnetic field when an electrical current is applied. The magnetic field interacts with a ferromagnetic armature positioned inside the hollow core of the spool, converting the electrical current into fast linear or rotary mechanical motion.

Rotary and linear holding solenoids are used in various industrial applications, including medical, automotive, machine automation, wind energy, marine, and agricultural applications.

- Rotary solenoids provide fast pivotal movement to a predefined angular position of 25°, 35°, 45°, 65° and 95° when powered.

- Linear solenoids develop force in a forward stroke direction. The largest solenoid can achieve stroke lengths of up to 40mm.

- Holding solenoids are solenoids without moving parts; they attract ferromagnetic material when powered.

Typical examples of application use include door locks, oxygen mask release mechanisms, gearbox interlocks, cash dispensing machines, amusement arcades, printers, laser positioning, parking ticket machines, card readers, conveyor feeds and diverters.

The majority of applications call for a solenoid that is unique in some way without requiring significant engineering. The duty cycle or operating voltage, the mounting, the return spring, the plunger end design, the electrical connections, and the insulation can be specified to suit the customer.

A solenoid manufacturer should provide the right product for a given application quickly and cost-effectively, which is done by adapting a standard design.

Sometimes, applications need a unique design, and we have the engineering experience to provide the solution.

Please get in touch with us for further information.